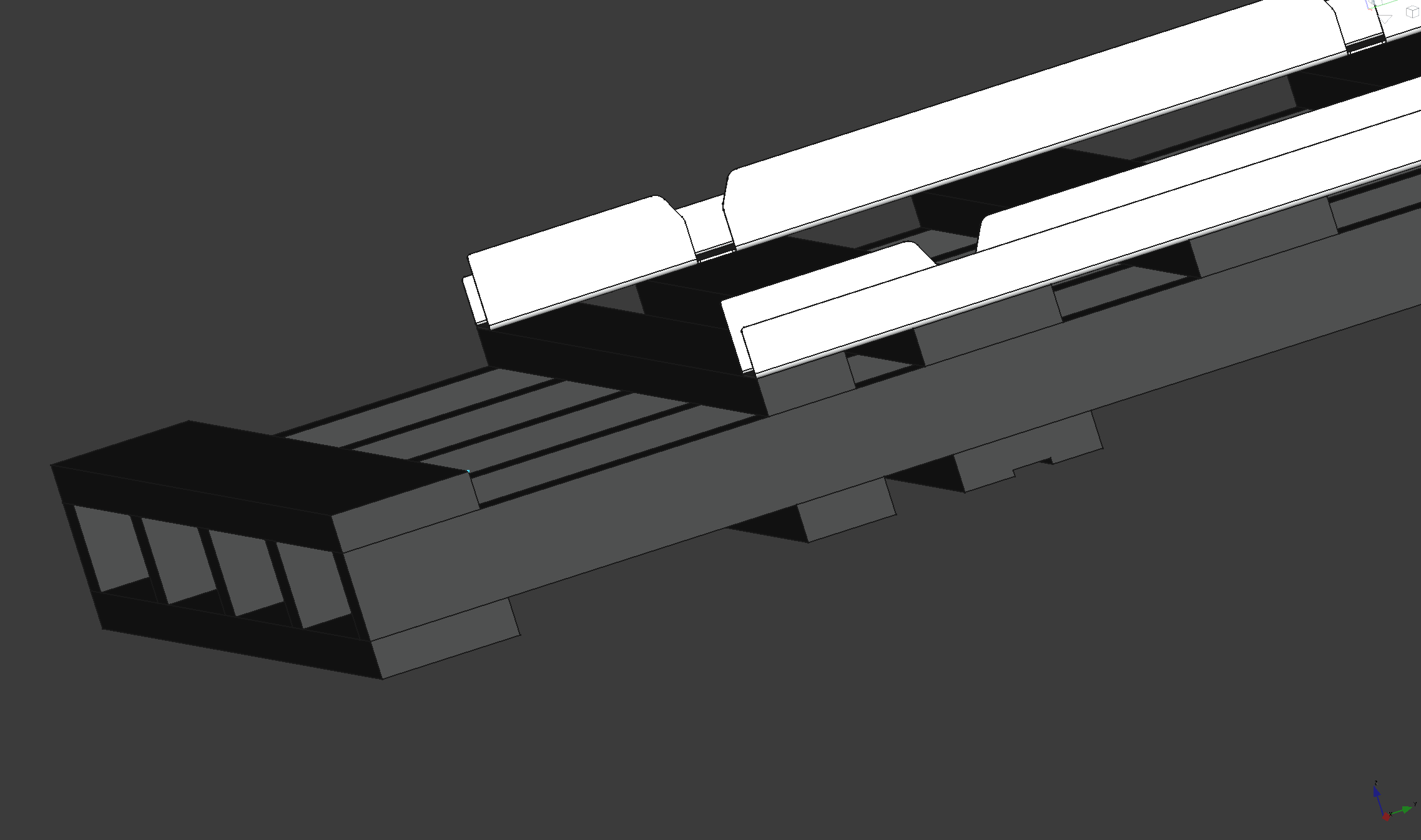

The 104” x 96” pallets above are for heavy products. They are to hold over 10,000lb of steel.

Custom Pallets

Key Highlights

Custom pallets are designed to your product’s exact specifications, reducing damage during shipping. The typical lead time for manufacturing a custom pallet can vary, but most orders are completed within 1 to 3 weeks depending on the complexity of the specification and current production schedules. Optimizing pallet design can lead to significant cost savings in your supply chain operations. Wood pallets can be customized for heavy-duty, oversized, or fragile goods.

Optimizing pallet design can lead to significant cost savings in your supply chain operations.

Wood pallets can be customized for heavy-duty, oversized, or fragile goods.

Choosing the right material and size enhances handling efficiency and warehouse storage.

Custom solutions improve weight distribution, protecting products and streamlining your supply chain.

International shipping requirements, like ISPM 15 heat treatment, are available for custom wood pallets.

Introduction

When it comes to your shipping needs, one size doesn't always fit all. Standard pallets can leave your products vulnerable to damage and lead to inefficient use of space. That's where custom pallets come in. These purpose-built platforms are tailored to your product's exact dimensions and weight, providing superior protection and a perfect fit. By integrating custom wood pallets into your supply chain, you can enhance safety, reduce costs, and streamline your entire logistics process from start to finish.

Understanding Custom Pallets and Their Advantages

Custom pallets are designed and manufactured to meet your unique requirements, unlike standard-sized options. This tailored approach ensures your products are perfectly supported, minimizing movement and the risk of damage. A thoughtful pallet design can significantly boost your supply chain efficiency.

By moving away from a one-size-fits-all solution, you can improve everything from handling to storage. The right custom wood pallets can make your shipping process smoother and more cost-effective. Let's explore the specific benefits and how different industries leverage these solutions.

Main Benefits Over Standard Pallets

Choosing custom pallets over standard pallets offers several key advantages for your supply chain. Since they are built to your product's exact dimensions, they provide a secure, stable, forklift accessible platform for whatever the size of your product. The only restriction then becomes the size of the truck. For smaller custom pallets, they provide a secure fit that standard options simply can't match. This precise engineering is crucial for protecting your goods.

This tailored fit leads to better weight distribution, which is essential for stability during transit. When a pallet is designed for a specific load, the risk of product damage drops significantly. This not only protects your inventory but also improves your overall supply chain operations. The benefits translate directly into financial gains.

Some of the main advantages include:

Reduced Product Damage: A perfect fit prevents items from shifting.

Lower Shipping Costs: Optimized designs can reduce pallet weight and size, cutting freight expenses.

Enhanced Safety: Proper support and weight distribution make handling safer.

Maximized Space: Custom sizes allow you to use warehouse and trailer space more effectively.

Custom Pallet Solutions for Different Industries

Many different sectors rely on custom pallets to meet their specific business needs. Standard dimensions are often not suitable for companies that handle heavy loads, fragile goods, or uniquely shaped products. For these various industries, custom wood crates and pallets are essential.

For example, manufacturers of heavy machinery need robust platforms that can support extreme weight without failing. In contrast, pharmaceutical industries require pallets that meet strict handling and safety standards to protect sensitive materials. Even the food and beverage industry benefits from custom designs that fit unique packaging footprints.

Here are a few industries that commonly use custom solutions:

Heavy machinery and equipment OEMs

Aerospace and defense suppliers

Automotive assembly plants

Food and beverage processors

Renewable energy component shippers

Custom block pallets, like the ones above, have multiple access points for forklifts. This is useful if you need to move an unbalanced load, where most of the weight is on one end.

The 104” x 96” pallets above are for heavy products. They are to hold over 10,000lb of steel.

The first step for our custom pallets is putting together a CAD of the pallet for the customer’s approval.

Winged pallets feature deck boards that extend past the edge of the ouside stringers. Winged pallets are useful because the stringers can be placed more directly under the weight of the product, and the wings are convenient for strapping.

Selecting the Right Custom Pallet Size and Material

Once you've decided to use custom pallets, the next step is to choose the right pallet size and material for your needs. These two factors are critical for ensuring your pallets perform correctly within your supply chain. The material, whether wood or plastic, affects durability, cost, and handling capabilities.

Similarly, the dimensions of the pallet directly impact how well it protects your product and fits into your storage and shipping systems. How do you decide between wood and plastic pallets? And what's the best way to determine the ideal dimensions for your shipping needs?

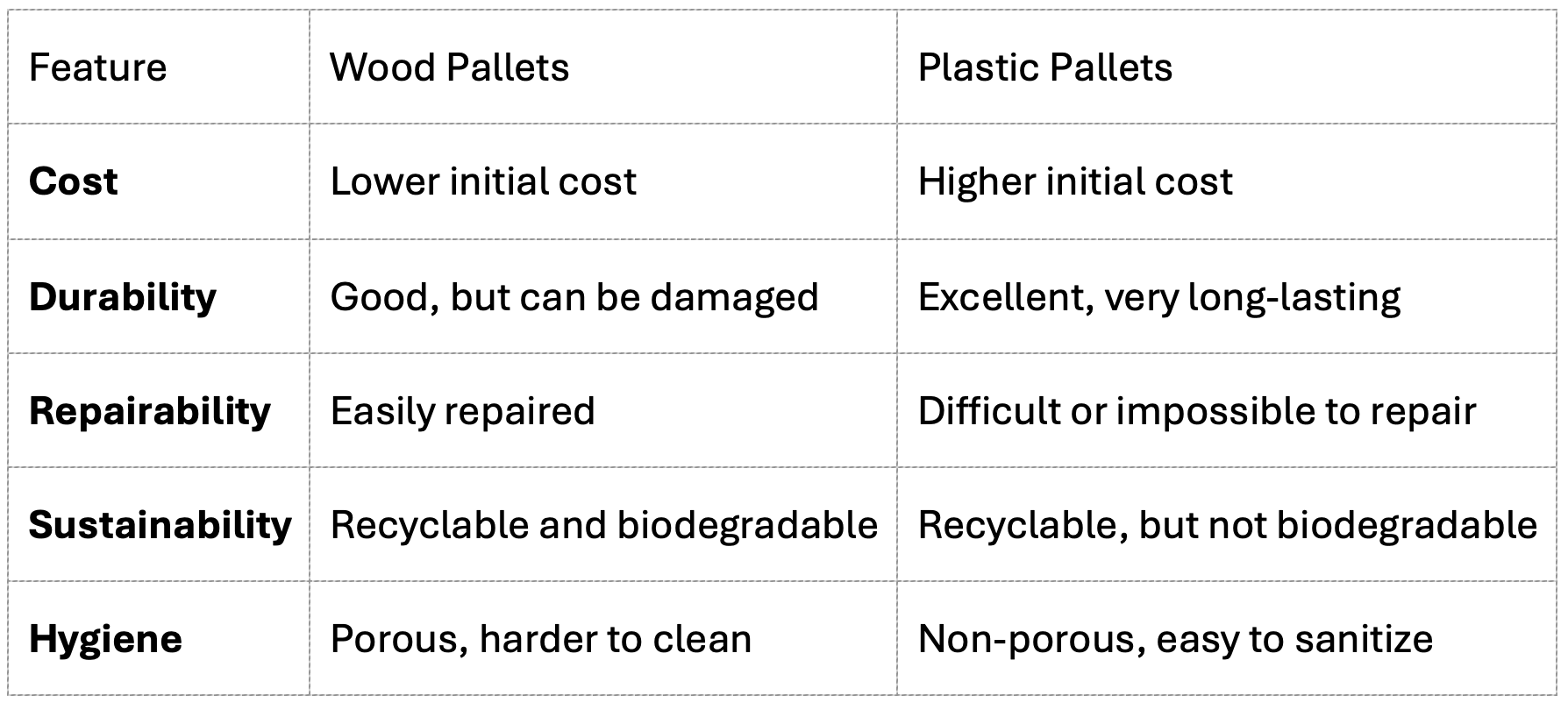

Wood vs. Plastic Custom Pallets

Both wood pallets and plastic pallets are available as custom solutions, but they offer different advantages. Wood pallets, made from materials like Southern Yellow Pine or mixed hardwood, are known for their high strength-to-weight ratio and cost-effectiveness. They are easily repaired and offer great versatility.

Plastic pallets, on the other hand, are praised for their exceptional durability and longevity. They are resistant to moisture and chemicals and are easy to clean, making them a popular choice for industries with strict hygiene standards. While they have a higher upfront cost, their long lifespan can lead to cost savings over time.

Choosing between them often depends on your specific application, budget, and sustainability goals. Both materials offer strong benefits, including recyclability, to support your operations.

Determining Ideal Dimensions for Your Shipping Needs

Moving beyond standard sizes to find your ideal pallet dimensions starts with your product. You need to know its exact dimensions and weight to begin the pallet design process. The goal is to create a platform that provides complete support without any wasted space or material.

Next, consider your handling processes and storage requirements. Will the pallets be moved with forklifts or pallet jacks? Do they need to fit into specific racking systems in your warehouse space? Answering these questions helps define the entry style (2-way or 4-way) and overall footprint of the pallet.

Advanced tools like the Pallet Design System (PDS) can simulate how a pallet will perform under specific loads, ensuring proper weight distribution and strength. This engineering-first approach confirms the design is safe and efficient before the first pallet is even built, guaranteeing it meets your exact needs.

Custom Pallet Design and Manufacturing Options

The pallet design and manufacturing process offers a wide range of custom solutions to meet any logistics challenge. Whether you need enhanced durability for repeated use or a heavy-duty design for large machinery, a custom build can be engineered to your specifications. You can even request features like strap notches or specific entry styles.

For international shipments, pallets can be heat-treated to meet ISPM 15 standards, ensuring smooth passage across borders. Exploring these options allows you to create the perfect platform for your products, from heavy-duty solutions to eco-friendly alternatives.

Heavy-Duty and Oversized Custom Pallet Solutions

Yes, custom pallets are ideal for heavy-duty and oversized shipments. When standard pallets can't handle the weight or size of your products, a custom pallet design is the perfect solution. These pallets can be engineered with thicker deck boards and stringers to support heavy machinery or other substantial items.

For maximum strength and handling versatility, block pallets are an excellent choice. Their design allows for four-way entry, ensuring compatibility with different types of forklifts and pallet jacks. This is crucial when maneuvering large or cumbersome loads in a busy warehouse or during shipping.

Key features for heavy-duty pallets include:

Thicker Lumber: Boards and stringers can be specified to the exact thickness needed for the load.

Block Pallet Design: Provides superior strength and four-way forklift access.

Reinforced Fasteners: Using screw-shank nails or clinch plates prevents boards from pulling apart under stress.

Eco-Friendly Materials and Recycling Practices

Sustainability is a key consideration in modern logistics, and custom pallets offer eco-friendly options. Many manufacturers are committed to responsible practices, including using recycled materials and minimizing material waste throughout the production process. This allows you to meet your shipping needs while also supporting your environmental goals.

Recycled pallets are a great example of this commitment. These pallets are thoroughly inspected, and those that meet strict quality standards are resold for use. Pallets that don't pass inspection are often repaired to become remanufactured pallets, extending their life and keeping them out of landfills.

Eco-friendly practices in pallet manufacturing include:

Using Recycled Materials: Incorporating pre-used pallets into the supply chain.

Recycling Residual Lumber: Turning material waste and scrap wood into other useful products.

Repair and Remanufacturing Programs: Giving damaged pallets a second life.

Conclusion

In conclusion, custom pallets offer tailored solutions that enhance efficiency and safety across various industries. By understanding the advantages of custom pallets over standard options, businesses can optimize their shipping processes and adapt to specific needs. Choosing the right size and material is crucial, whether you opt for wood or plastic, ensuring durability and sustainability in your operations. With increasing demand for eco-friendly solutions, custom pallets made from recyclable materials can help minimize environmental impact while meeting industry standards. Embrace the potential of custom pallets to elevate your logistics strategy. If you're ready to find the perfect pallet solution for your business, don't hesitate to reach out for more information!

Frequently Asked Questions

How does the process of ordering custom pallets work in the United States?

Ordering a custom pallet typically starts with a consultation to discuss your specification and supply chain needs. A team of experts will then model a design, often providing a prototype for approval. Once you confirm the design, full production begins, followed by delivery, ensuring exceptional service from start to finish.

What certifications are required for custom pallets in international shipping?

For international shipping, wood pallets must meet ISPM 15 certification standards. This involves heat-treating the wood, including softwood lumber, to eliminate pests. The pallet is then stamped with an official mark, confirming it complies with these international standards and can cross borders without issue.

Are bulk ordering options available for custom pallets?

Yes, bulk ordering options are widely available for custom pallets. Purchasing in larger quantities is a great way to ensure you have a steady supply while often securing a better price per unit. This can help you lower your overall shipping expenses, reduce long-term replacement costs, and better manage freight costs.